Energy Efficiency

The purpose of energy efficiency is to reduce the primary energy consumption of industrial sites and, as a result, their greenhouse gas emissions. This decarbonisation lever is at the heart of ALLICE's activity.

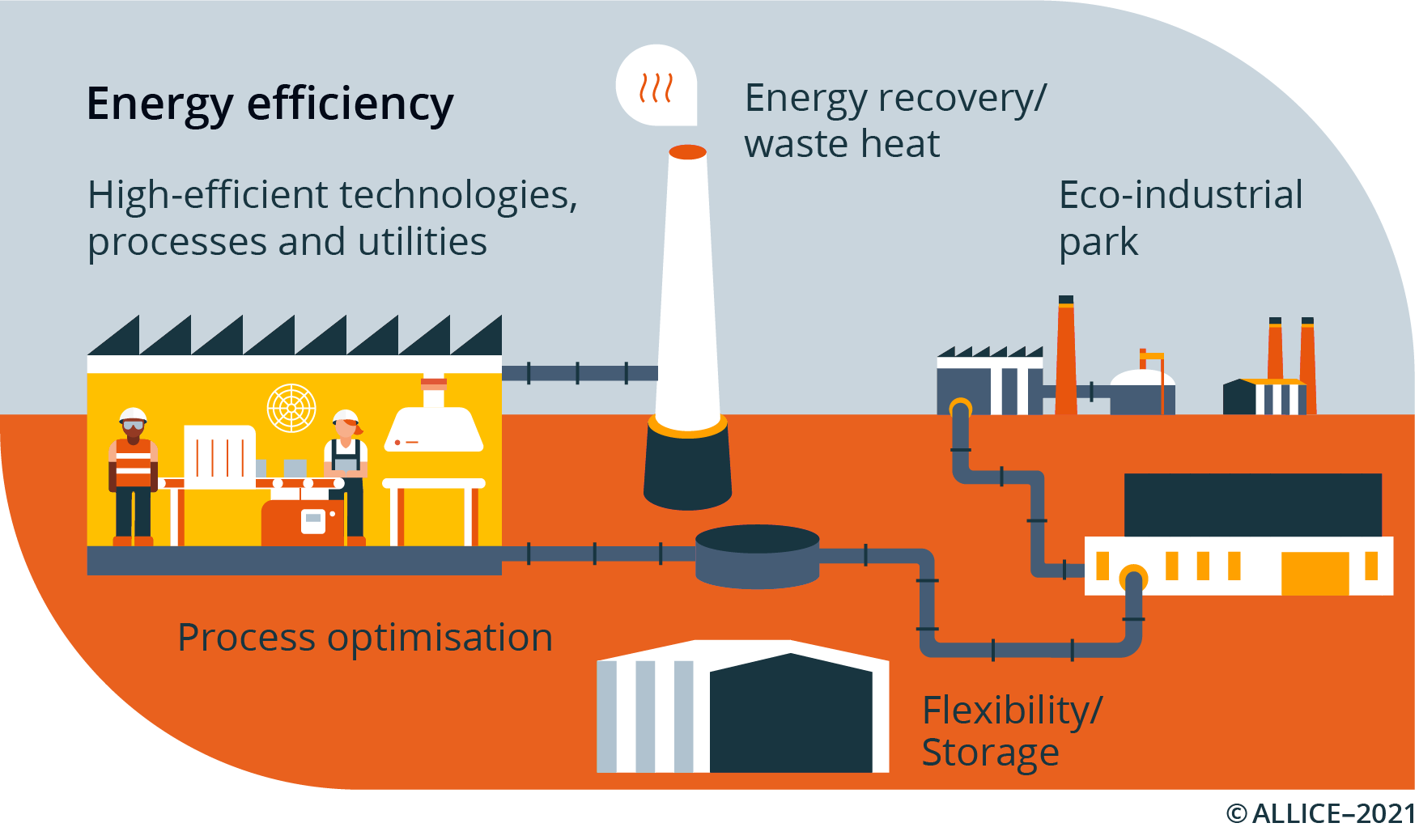

Production system design has a strong influence on energy performance at different scales: the technology itself, the plant system and the industrial site within its territory.

- The technology and process scale

Improving energy efficiency involves improving the components that make up an industrial process or utility, such as a heat exchanger, a boiler, a furnace, a compressor, a pump, a heat engine, etc. Optimizing the performance of energy-intensive technological building blocks is a first lever for accelerating energy transition. Improving energy efficiency also involves working on the unitary operation itself, by proposing new concepts or improving the core process.

ALLICE has carried out various actions at this very detailed and efficient scale.

Several studies or state of the art overviews on topics such as:

ALLICE has carried out various actions at this very detailed and efficient scale.

Several studies or state of the art overviews on topics such as:

- Solutions to prevent clogging of heat exchangers for optimum heat recovery (publication imminent)

- High-performance ventilation solutions

- Efficient cooling in industry

- Mature and emerging solutions for very high temperature heat pumps

- Heat storage technologies in industry

- The performance of heat exchangers used in industrial processes

- Technologies (advanced and alternative) for cold production

- Modelling of drying phenomena in an industrial convective dryer

- A study on the different solutions available for the decarbonation and energy efficiency of specific unitary operations.

- A state of the art overview of efficient ventilation technologies

- The plant and process scale: a systemic approach

To reduce energy consumption and decarbonize the operation of an entire site, it’s also possible to act at the process or workshop structure level. This approach, known as systemic analysis, consists of graphic or mathematical methodologies used to optimize the design or structure of an existing process. It concerns for example:

- The optimal integration of unitary operations, such as drying

- The implementation of energy and heat recovery solutions

- The development of local storage and distribution networks (using vectors such as hydrogen)

- The optimization of energy networks

- Flexibility so that the plant can respond to demand fluctuations and adapt its energy consumption to distribution network availability. This flexibility can even lead to load shedding that can be offset by self-generation.

ALLICE has run several projects at this scale, including:

- A study on the deployment potential of industrial heat recovery projects

- A study on the decarbonisation of cooking and drying processes

- A state-of-the-art study of heat-to-electricity technologies

- A study on very high temperature heat recovery (>200C°)

- A study on heat recovery from industrial fumes

- A study on the potential of heat storage in industry

- Une étude sur la cogénération et la trigénération et leurs opporunités d'amélioration des performances des systèmes de valorisation de chaleur fatale.

- The eco-industrial park scale: the industrial site in its territory

Complexity generated by the presence of many companies makes it necessary to develop specific methodologies. Among others, strong criteria such as flexibility or resilience in case of the failure of one of the actors become fundamental.

During its Club Primes, ALLICE shares experiences with its members, for example, EDF's consideration of Industrial and Territorial Ecology in its activity, OSIRIS Economic Interest Group’s experience with synergies on the Roussillon platform, or the presentation by Kalundborg Symbiosis of the operation of the Kalundborg eco-industrial park (Denmark).

In 2021, ALLICE conducted a state of the art overview on the models that can promote the emergence of industrial eco-industrial parks.